Textile Sizing Applications

Capabilities for the Textile Yarn and Glass Fiber Sizing application

In production – modified Starches:

Top-Size® 555

Medium viscous Ester 150-250 mPa.s

Top-Size® 556

Low viscous Ester 70-120 mPa.s

Top-Size® 562

Low Viscous Starch Ether 30-40 mPa.s

cold water soluble

Top-Size® CMS 60

– Low viscous Carboxymethyl Starch ether 60-100 mPa.s

– Delayed cold water soluble, fully activated after cooking for 20-30minutes at 90-94°C, stable solutions

– de-sizing by hot washing.

Top-Size® PS LV

– Low viscous modified PS Starch 60-100 mPa.s

– Delayed cold water soluble

– fully activated after cooking for 20-30minutes at 90-94°C, stable solutions

– de-sizing by enzymes.

For above viscosities; 10% w/w solution, heated30-45min 94°C, Brookfield RVT 20rpm spl 1 70°C

Cross-over List

Top-Size® 555 Emsize E5, Enziplast A550, Starch Ester

Top-Size® 556 Kollotex 1250, Emsize E9, Starch Ether

Top-Size® CMS 60 Quicksolan CMS, Emsize CMS60, Carboxymethyl Starch

In Development phase

Top-Size® 2455 Starch

Vinyl Acetate Graft Co-Polymer 30-60 mPa.s

Top-Size® PS MV

Medium/High viscous modified PS Starch 400-500 mPa.s

For above viscosities; 10% w/w solution, heated30-45min 94°C, Brookfield RVT 20rpm spl 1 70°C

Please consult Technical Datasheet for detailed Product information

Top-Size® PS

represents the latest technical developments in applying a smooth, clear, strong and highly flexible sizing film around the yarn.

Traditional modified starches form brittle sizing films with limited tenacity/elongation, this a compensated by formulating a size with additional additives like Wax, PVA, Acrylates or CMC.

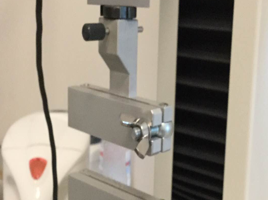

Flexibility, elongation and tensile strength of the sizing film covering the yarn are very important parameters for an optimal sizing result.

Top-Size® PS

Young’s Modulus (Elastic Modulus) reaches 700-780 N/mm2 , with 207N/mm2 for a tradional starch sizing film, a 275% increase.

Top-Size® PS

elongation(before break) at 23.02% is very favourable compared to the 2-3% for a standard sizing formulation., a difference of 650%,

Top-Size® PS

Tensile strength 12.1 Mpa(N/mm2) is 200% higher than a 70% Starch/30% PVA blend, and similar to the tensile strength of 100% PVA.

Top-Size® PS

Yarn Sizing products are the result of HANSELAND R&D work. Top-Size® PS granular shape powder reduces dust formation when handling, 100% natural, and thus 100% biodegradable. REACH registrationis not required.

Comparison – Top-Size® PS sizing film

with traditional sizing products.

Sizing Product Mpa Elongation

N/mm2 %

Top-Size® PS 12.1 23.02

Starch Ester 8.4 1.69

Starch/PVA (30:70 ratio) 8.7

Starch/PVA (50:50 ratio) 5.3

Starch/PVA (70:30 ratio) 4.0 49.6

PVA 10.9 334.6

Top-Size® PS sizing film Young’s Modulus 275% higher, elongation 650% higher compared a starch sizing film, and Tensile strenght is 200% increased compared to a traditional 70/30 blend of starch and PVA.